Multi-metal 3D printer to boost Australia's aerospace manufacturing

Image: Nick Rains (CSIRO)

The introduction of a new sophisticated 3D printer in Melbourne with the iLAuNCH Innovator program aims to boost room objectives by generating aerospace components that are lighter, quicker, and stronger, inevitably making them extra affordable and effective.

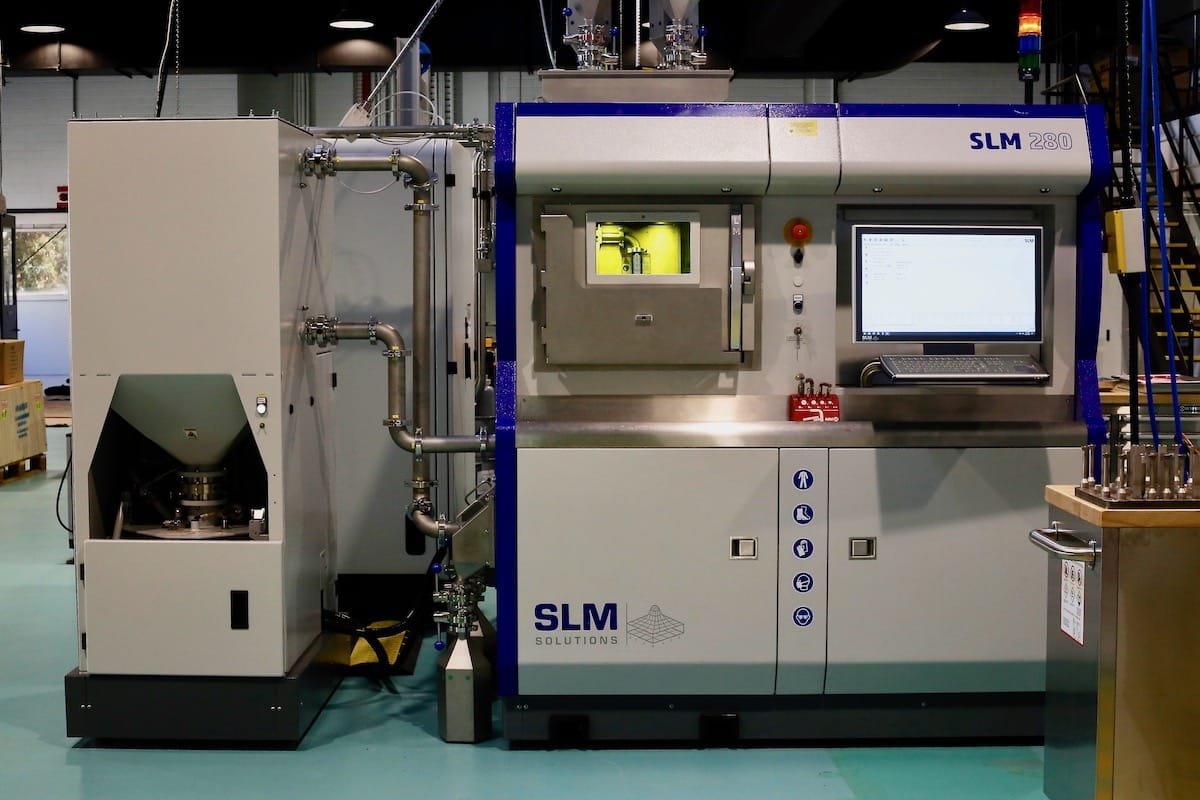

Australia has just one high-tech printer of its kind. Dr. Joni Sytsma, from iLAuNCH, shared that this manufacturing machine's one-of-a-kind capacity notes a significant innovation in Australian manufacturing. iLAuNCH is thrilled to introduce brand-new manufacturing chances for locally produced products, making it an introducing effort in the southern hemisphere. The Nikon SLM-280 at CSIRO's Lab22 facility will print metals side-by-side in one continual print.

The technology is optimal for aerospace and space applications, where high performance and light-weight materials are important design considerations. Sytsma discussed that Australian businesses producing satellites and rockets have a the chance to enhance their designs and improve performance sfully in Melbourne with a shortened manufacturing timeline. It supplies designers with the flexibility to consolidate components, reducing both mass (and expense), enabling calculated weight decisions.

According to Sytsma, the innovative innovation is anticipated to create brand-new high-performance alloys that can hold up against extremely high heat, paving the way for hypersonic air travel in the future. The sophisticated manufacturing capability of this technology will certainly help with the creation aerospace products that will benefit the whole aerospace community.

"We invite researchers and industry experts from Australia to utilize our modern innovation at CSIRO's Lab22 Development Centre”, a premier location for metallic additive manufacturing in Clayton, Victoria. This provides the opportunity to be extended to those looking for to discover the potential of ultra-high efficiency applications, under the guidance of Dr. Cherry Chen, CSIRO's senior research scientist.

“We've collaborated with various firms to develop cutting-edge remedies for the aerospace sector. Our collaboration work with CellCore GmbH in Berlin has actually caused the creation of a monolithic drive chamber for rocket propulsion engines, including a distinctive lattice framework. Furthermore, we've partnered with the VTT Technical Research Study Centre of Finland to design a hydraulic valve block that boasts a 66% decrease in dimension and 76% weight decrease. Additionally, our deal with ASCO, a Belgian aerospace business, has caused the development of a gooseneck bracket that considerably lowers the buy to fly ratio from 17 to 1.5, while also attaining a 31% decrease in weight.”

"Delivering Laser Powder Bed Blend technology to produce an absolutely functionally graded product element to CSIRO marks the first time the innovation has been demonstrated outside of Germany. This modern technology establishes a new cornerstone in the aerospace and defence and demonstrating to the space industry what is possible," claimed Donald Godfrey, Nikon SLM Solutions, international director, service advancement for aeronautics and defence.

For iLAuNCH Pioneer jobs, SLM 280 modern technology will certainly make potential area objectives a lot more economical and reliable by producing lighter, quicker and extra robust space elements.

Original article: https://www.manmonthly.com.au/multi-metal-3d-printer-to-boost-australias-aerospace-manufacturing/